Why Heat Exchanger Repair Matters for Your Home’s Safety and Comfort

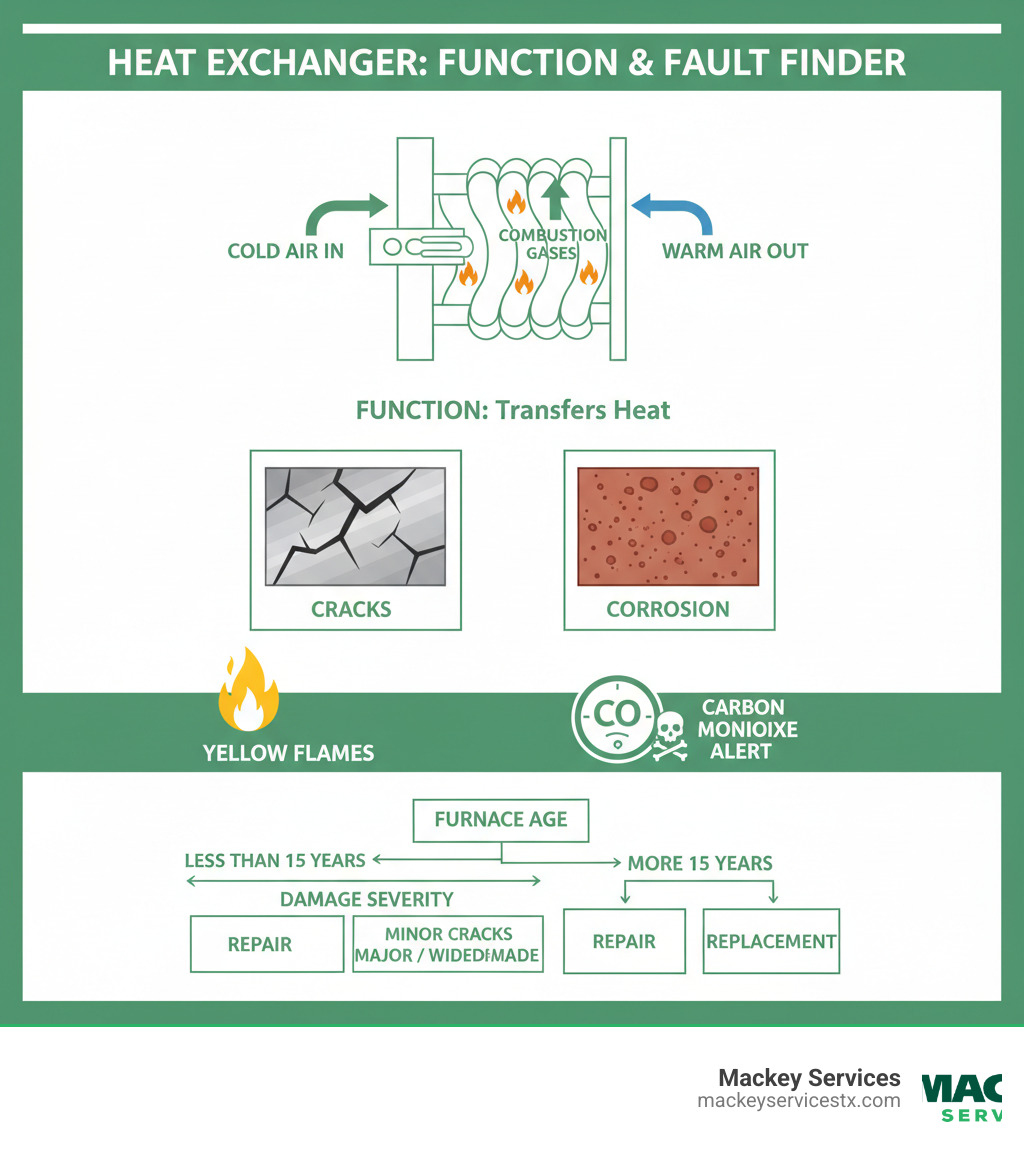

Heat exchanger repair is a critical service that addresses damage to the component in your furnace responsible for safely transferring heat. When this metal chamber develops cracks or corrosion, it can release dangerous carbon monoxide into your home and reduce heating efficiency.

Quick Overview: What You Need to Know About Heat Exchanger Repair

- Common warning signs: Yellow pilot light, soot buildup, strange odors, reduced heating, carbon monoxide detector alerts

- Repair options: Surface preparation, epoxy composite rebuilding, protective coating application, re-tubing, or gasket replacement

- When to repair vs. replace: Repair works best for newer furnaces with minor damage; replacement is better for systems over 15 years old with frequent issues

- Safety priority: Always requires professional assessment due to carbon monoxide risks

If you’re searching for reliable HVAC services in Houston or need immediate assistance, contact Mackey Services for expert diagnosis and repair.

Heat exchangers endure extreme stress from heating cycles and moisture, leading to metal fatigue and cracks. Since a failing heat exchanger poses serious health risks like carbon monoxide poisoning, knowing when to repair or replace is essential.

Fortunately, many issues can be fixed through professional repair using advanced materials like epoxy composites and industrial coatings. These methods can restore structural integrity and extend equipment life. However, the decision to repair or replace depends on your furnace’s age, the extent of the damage, and its overall condition.

Understanding Heat Exchanger Damage: Common Causes and Warning Signs

Your furnace’s heat exchanger is the workhorse of your heating system, transferring warmth while keeping dangerous exhaust gases safely contained. This relentless duty leads to metal fatigue from constant heating and cooling, thermal stress that creates cracks, and corrosion from moisture and combustion byproducts. Factors like rust, soot buildup, and reduced airflow also contribute to potential failure. Recognizing the warning signs early can help you address issues when heat exchanger repair is still a viable option.

Signs Your Heat Exchanger Needs Attention

Your furnace communicates problems through several warning signs. Knowing what to look for is key.

- Yellow Furnace Flame: A yellow or orange flame, instead of a crisp blue, indicates incomplete combustion, a sign that gases may not be venting properly.

- Soot Around the Furnace: Black, powdery residue on or near your system points to combustion issues, often linked to a compromised heat exchanger.

- Strange Noises: Loud banging, popping, or whistling can signal damaged internal components. If your furnace starts making new sounds, it’s time for a professional inspection.

- Water Leaks: Pooling moisture around the furnace base can indicate condensation issues or cracks in the heat exchanger.

- Reduced Heating Performance: Cold spots or inconsistent temperatures often mean the heat exchanger is no longer transferring heat efficiently.

- Carbon Monoxide Detector Alerts: If your detector sounds, get everyone out of the house immediately and call 911. A cracked heat exchanger can leak this colorless, odorless gas. Do not investigate it yourself—it’s an emergency.

For a comprehensive look at what else might be going wrong with your system, check out our guide on identifying the most common problems with furnaces.

Primary Causes of Failure

Understanding what causes these problems can help you prevent them.

- Corrosion: This is a common culprit. Electrochemical processes, accelerated by moisture, cause the metal to break down.

- High Operating Temperatures: Constant expansion and contraction from heating and cooling cause stress fractures and age-related wear and tear.

- Moisture Buildup: Condensing combustion gases can create an acidic liquid that eats away at metal surfaces, a common issue in high-efficiency furnaces.

The combination of these factors explains why even well-maintained heat exchangers eventually need attention. If you’ve noticed a flame that’s not quite the right color, you’ll want to read more about why an orange furnace flame is always a sign of trouble. The key takeaway is to never ignore the warning signs, as a small issue can quickly become a safety hazard.

The Professional Heat Exchanger Repair Process

When your heat exchanger shows signs of trouble, calling a professional is essential for your family’s safety. The process begins with a thorough diagnosis using specialized tools, like borescopes, to inspect for cracks and corrosion. We follow strict safety protocols, as there’s no room for shortcuts with potential carbon monoxide risks. Depending on the damage, repairs can often be handled onsite, minimizing disruption to your routine.

Step-by-Step Guide to a Technical Heat Exchanger Repair

A professional heat exchanger repair follows a precise sequence to ensure a lasting and safe solution.

- Safety & Inspection: The process begins by shutting off power and gas to the furnace. A technician then performs a detailed inspection to assess the damage.

- Surface Preparation: To ensure repair materials bond correctly, the damaged area is thoroughly cleaned and stripped of rust and contaminants using methods like grit blasting.

- Rebuilding: High-strength, industrial-grade epoxy composites are applied to rebuild cracked or thinned metal, restoring structural integrity.

- Protective Coating: A fluid-grade ceramic or epoxy coating is applied over the repair. This creates a durable barrier against future corrosion and chemical attack.

- Curing & Final Testing: The materials are allowed to cure completely. Afterward, a final inspection and pressure test verify the heat exchanger is sealed and safe before the furnace is put back into service.

For those interested in the technical details of how these advanced coating systems work, A guide to heat exchanger repair with coatings provides comprehensive information.

Repair Needs for Different Heat Exchanger Types

Not all heat exchangers are the same, and the repair approach depends on the design. Residential furnaces typically use a clam-shell or tubular design. Commercial systems, like shell-and-tube or plate exchangers, require different techniques, such as re-tubing or gasket replacement. A professional technician will identify the type and apply the correct repair method.

The Role of Industrial Coatings and Epoxies

Modern industrial coatings and epoxy composites have revolutionized heat exchanger repair.

- Epoxy Composites: High-strength materials like Belzona 1111 (Super Metal) are used to rebuild damaged metal sections. They restore structural integrity without welding, a major safety advantage known as a “no hot work” repair.

- Ceramic Coatings: Applied after rebuilding, these coatings create a protective barrier against corrosion, erosion, and chemical attack, helping the repair withstand thermal stress.

- Key Benefits: When applied by a trained professional, these advanced materials can add years to a heat exchanger’s service life. The cold-curing process is safer, faster, and less disruptive for your home.

Repair vs. Replace: Making the Right Decision for Your Furnace

When your heat exchanger is damaged, you face a big decision: repair it or replace the entire furnace? There’s no single right answer. The best choice depends on your furnace’s age, the severity of the damage, its overall condition, and your long-term goals. Think of it like deciding whether to fix an old car or buy a new one—you have to consider the whole picture.

| Factor | Repair Heat Exchanger | Replace Entire Furnace |

|---|---|---|

| Furnace Age | Ideal for newer furnaces (under 10 years) | Recommended for older furnaces (15+ years) |

| Damage Severity | Suitable for minor cracks or isolated corrosion | Better for extensive damage or multiple issues |

| Warranty Status | Often covered if furnace is under warranty | New furnace comes with a new warranty |

| Overall System Condition | Good, with no other major components failing | Deteriorating, with frequent breakdowns or high repair costs |

| Energy Efficiency | Maintains current efficiency | Significant gains possible with new, high-efficiency models |

| Long-term Reliability | Can extend life for several years, depending on repair | Provides a fresh start, more reliable for 15-20 years |

| Safety Concerns | Repair must fully address carbon monoxide risks | New unit eliminates existing safety concerns |

When to Choose Repair

Heat exchanger repair makes excellent sense in several situations. If your furnace is relatively young (under ten years old) and has been otherwise reliable, repair is usually the smart move. Minor damage, like small cracks or localized corrosion, responds well to modern repair techniques using epoxy composites and protective coatings. The repair may also be partially or fully covered if your furnace is still under the manufacturer’s warranty, making it a clear choice. Essentially, if the furnace is in good shape apart from the heat exchanger, a targeted repair can add years of service life without the expense of a full replacement.

For homeowners across the Greater Houston Area, professional assessment is key to making this decision safely. Learn more about The importance of professional gas furnace repair and why cutting corners on gas appliances is never worth the risk.

When to Consider Replacement

Sometimes, replacing your furnace is the wiser long-term investment.

- Age: Furnaces typically last 15-20 years. If yours is approaching this age, a failing heat exchanger is often a sign that other components will soon fail.

- Frequent Breakdowns: If you’re already paying for frequent repairs, those costs can add up. Putting that money toward a new, reliable system is often more economical.

- Energy Efficiency: A new high-efficiency furnace (95%+) can offer significant savings on utility bills compared to an older model (60-70% efficiency).

- Obsolete Parts: For very old furnaces, finding replacement parts can be difficult or impossible.

- Safety: If damage is extensive, a repair may not be able to guarantee protection from carbon monoxide. In this case, replacement is essential for your family’s safety.

Wondering if it’s time to think bigger than just your furnace? Check out these Signs it’s time to upgrade your HVAC system for a comprehensive look at when a full system replacement makes sense.

The Importance of Quality Parts and Preventative Maintenance

For a critical job like heat exchanger repair, the quality of the parts and materials used is paramount for your family’s safety and your system’s reliability. A well-maintained furnace with quality components operates efficiently and safely, and the combination of genuine parts and preventative care is the best defense against unexpected breakdowns.

Why Genuine Parts Matter in a Heat Exchanger Repair

When repairing a heat exchanger, you can choose between Original Equipment Manufacturer (OEM) parts and aftermarket alternatives. Genuine OEM parts are engineered for your specific furnace model, ensuring a perfect fit and proper function. They are built from materials designed to withstand your furnace’s extreme operating conditions.

Aftermarket parts may be cheaper but carry risks. An improper fit can allow dangerous gases to escape, reduce efficiency, or stress other components. In fact, studies show that 88% of all processors have experienced equipment failure with non-OEM parts. Using genuine parts maintains your system’s safety and reliability, preventing premature failure.

How Regular Maintenance Prevents Costly Repairs

The best repair is one you never need, and regular maintenance is key to prevention.

During an annual inspection, technicians look for early warning signs like tiny cracks or corrosion, allowing for minor fixes before they become major emergencies. Cleaning is also crucial, as buildup on the heat exchanger traps heat, forces the furnace to work harder, and accelerates corrosion.

One of the simplest tasks is changing your air filter every 1-3 months. A clogged filter restricts airflow, causing the furnace to overheat and stressing the heat exchanger, which can lead to cracks.

Finally, comprehensive performance checks of the flame, gas pressure, and electrical connections ensure your furnace is running safely and efficiently. Identifying issues early through maintenance is the best way to extend your furnace’s life and avoid the stress of a sudden breakdown.

For detailed guidance on keeping your heating system in top condition, take a look at Your guide to furnace maintenance.

Frequently Asked Questions about Heat Exchanger Repair

When your furnace isn’t working right, it’s natural to have concerns. We’ve answered some of the most common questions we hear from homeowners to help you make informed decisions.

Can a cracked heat exchanger be repaired?

Yes, in many cases, a cracked heat exchanger can be repaired. For minor cracks, specialized methods using advanced epoxy composites or even welding can be effective. However, a professional assessment is essential. A technician must inspect the crack’s size and location, and the overall condition of the metal. If the damage is extensive or the metal is too degraded, repair is not a safe option, as it may not prevent carbon monoxide leaks. In these cases, replacement is necessary for your family’s safety.

How long does a heat exchanger repair last?

A professional heat exchanger repair using high-performance materials can extend its life for several years, with some documented repairs lasting for decades under proper conditions. The longevity depends on the quality of the workmanship, the materials used, and the original extent of the damage. Regular maintenance after the repair is also essential to prevent new problems. Annual inspections and regular filter changes will help ensure the repair remains effective for years to come. For guidance on keeping your system in top shape, check out Your guide to furnace maintenance.

Is a damaged heat exchanger dangerous?

Yes, a damaged or cracked heat exchanger is extremely dangerous. Its job is to keep combustion gases, including deadly carbon monoxide, separate from your home’s air. A crack allows this colorless, odorless gas to leak into your living space. Carbon monoxide exposure can cause flu-like symptoms, unconsciousness, or even death.

This is why working carbon monoxide detectors are vital. If your detector ever goes off, evacuate immediately and call emergency services. Do not try to investigate the source yourself. A damaged heat exchanger requires immediate professional attention to protect your family.

Your Partner in Safe and Reliable Heating

Deciding between heat exchanger repair and replacement requires careful consideration of your furnace’s age, the extent of the damage, and your long-term goals. As we’ve covered, a repair can be a cost-effective solution for newer systems with minor issues, while replacement is often wiser for older, less efficient furnaces with significant safety concerns.

Every situation is unique, which is why a professional assessment is crucial. At Mackey Services, we’ve spent 30 years providing honest answers and reliable solutions to families across the Greater Houston Area. Our A+ BBB rating reflects our commitment to your safety and comfort. Our experienced team uses quality parts and proven methods to guide you toward the best decision for your home.

If you’re experiencing furnace problems or want the peace of mind of a professional inspection, we’re here to help. For expert diagnosis and professional heating repair in Galveston and the surrounding communities, count on Mackey Services. We are dedicated to keeping your home warm, comfortable, and safe.